08 Jul 2024

INTRODUCTION:

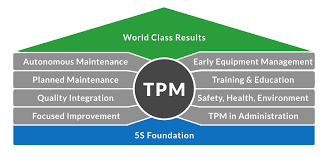

Total Productive Maintenance (TPM) is a proactive approach to maintenance management that aims to maximize the efficiency and effectiveness of equipment and processes within a manufacturing facility. Originating in Japan in the 1960s, TPM has evolved into a widely adopted methodology embraced by industries worldwide. At its core, TPM focuses on empowering employees, opti...