INTRODUCTION:

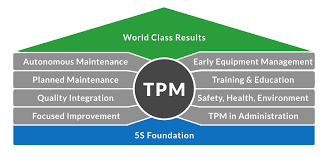

Total Productive Maintenance (TPM) is a proactive approach to maintenance management that aims to maximize the efficiency and effectiveness of equipment and processes within a manufacturing facility. Originating in Japan in the 1960s, TPM has evolved into a widely adopted methodology embraced by industries worldwide. At its core, TPM focuses on empowering employees, optimizing equipment reliability, and eliminating losses to drive continuous improvement. Central to TPM are its eight fundamental pillars, each playing a crucial role in achieving operational excellence and fostering a culture of continuous improvement.

EXPLORING TPM:

TPM is not merely a maintenance strategy but a holistic philosophy that permeates every aspect of an organization’s operations. It emphasizes collaboration across departments, from maintenance and production to quality assurance and management, to achieve common goals. At its heart, TPM seeks to instill a sense of ownership and responsibility among employees for the equipment they operate and maintain.

THE EIGHT PILLARS OF TPM:

- Focused Improvement: This pillar emphasizes the importance of continuous improvement efforts targeted at eliminating losses and inefficiencies in the production process. It encourages frontline employees to identify and address root causes of problems through structured problem-solving methodologies such as PDCA (Plan-Do-Check-Act) or DMAIC (Define-Measure-Analyze-Improve-Control).

- Autonomous Maintenance: In autonomous maintenance, operators take ownership of routine cleaning, inspection, and minor maintenance tasks for their equipment. By empowering operators to care for their machines, TPM aims to prevent breakdowns, reduce unplanned downtime, and improve overall equipment effectiveness (OEE).

- Planned Maintenance: Planned maintenance involves systematic scheduling of maintenance activities based on equipment condition, usage, and historical performance data. By conducting maintenance proactively rather than reactively, organizations can minimize disruptions to production schedules and extend equipment lifespan.

- 4. Early Equipment Management (EM): Early equipment management focuses on optimizing the design, installation, and commissioning of new equipment to ensure reliability and maintainability throughout its lifecycle. By involving maintenance and production teams early in the equipment acquisition process, organizations can identify and mitigate potential issues before they arise.

- Quality Maintenance: Quality maintenance aims to prevent defects and deviations from specifications by addressing equipment-related quality issues. It involves implementing measures such as error-proofing (poka-yoke), standardizing work procedures, and conducting regular quality checks to ensure consistent product quality.

- Training & Education: TPM recognizes the importance of investing in employee training and development to build technical skills, foster a culture of continuous learning, and promote cross-functional collaboration. By providing employees with the knowledge and tools they need to succeed, organizations can enhance overall performance and adaptability.

- Administrative & Office TPM: While TPM traditionally focuses on shop-floor operations, administrative and office functions also play a crucial role in supporting overall business objectives. This pillar extends TPM principles to administrative processes, such as order processing, inventory management, and office ergonomics, to eliminate waste and improve efficiency.

- Safety, Health, and Environment (SHE): TPM places a strong emphasis on creating a safe and healthy work environment for employees while minimizing the environmental impact of operations. By integrating safety, health, and environmental considerations into everyday practices, organizations can protect their most valuable asset—their workforce—and demonstrate corporate responsibility.

CONCLUSION:

Total Productive Maintenance (TPM) offers a comprehensive framework for achieving operational excellence, enhancing equipment reliability, and driving continuous improvement in manufacturing environments. By embracing the eight fundamental pillars of TPM and fostering a culture of collaboration, empowerment, and continuous learning, organizations can unlock their full potential and thrive in today’s competitive landscape. As TPM continues to evolve and adapt to changing industry trends, its principles remain timeless, guiding organizations on their journey towards excellence and sustainable growth.